The Blue Economy CRC Hydrogen Microgrid

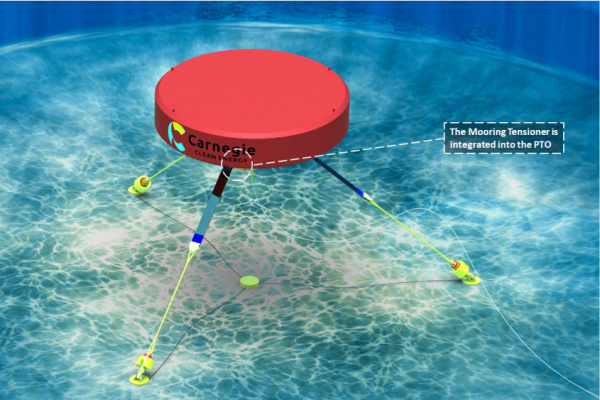

The Blue Economy CRC has embarked on a demonstration project to develop, deploy and operate a DC (Direct Current) hydrogen microgrid at an offshore location, most likely to support aquaculture operations.

The Blue Economy CRC Hydrogen Microgrid

The Blue Economy CRC has embarked on a project to deploy a DC (Direct Current) hydrogen microgrid at an offshore location, most likely in association with aquaculture.

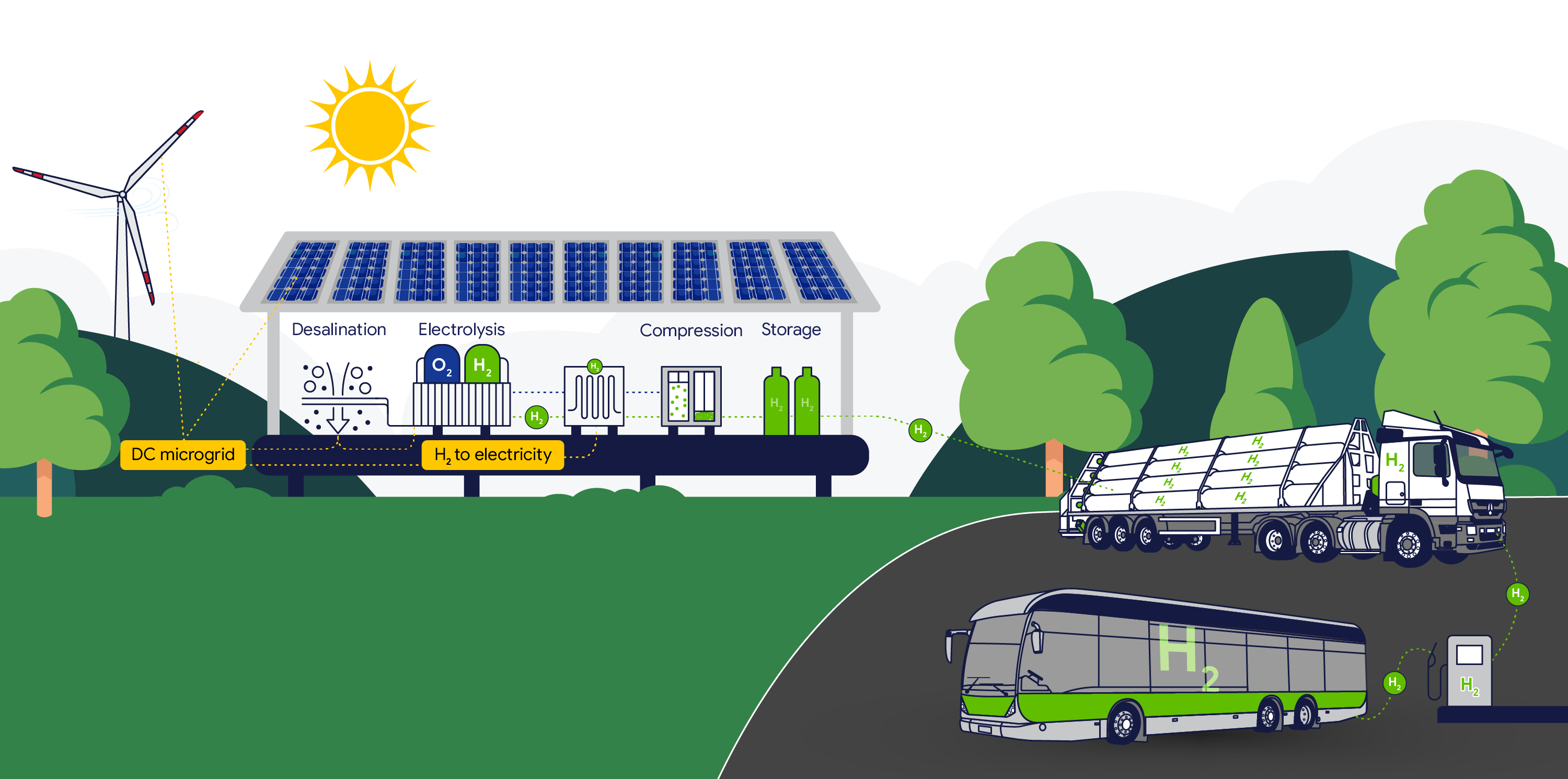

The project will be carried out in two phases: onshore and offshore.

The final configuration of the offshore microgrid is to be determined, but it will be powered by renewable energy capture and provide electricity to generate hydrogen as a means of storing energy and for powering vessels.

The onshore microgrid is a simplified version of the ultimate offshore microgrid. The onshore hydrogen microgrid will supply hydrogen fuel to power Metro Tasmania’s fuel-cell buses and other potential offtakes, and support research into the design and operation of DC hydrogen microgrids for applications such as aquaculture and vessel operations.

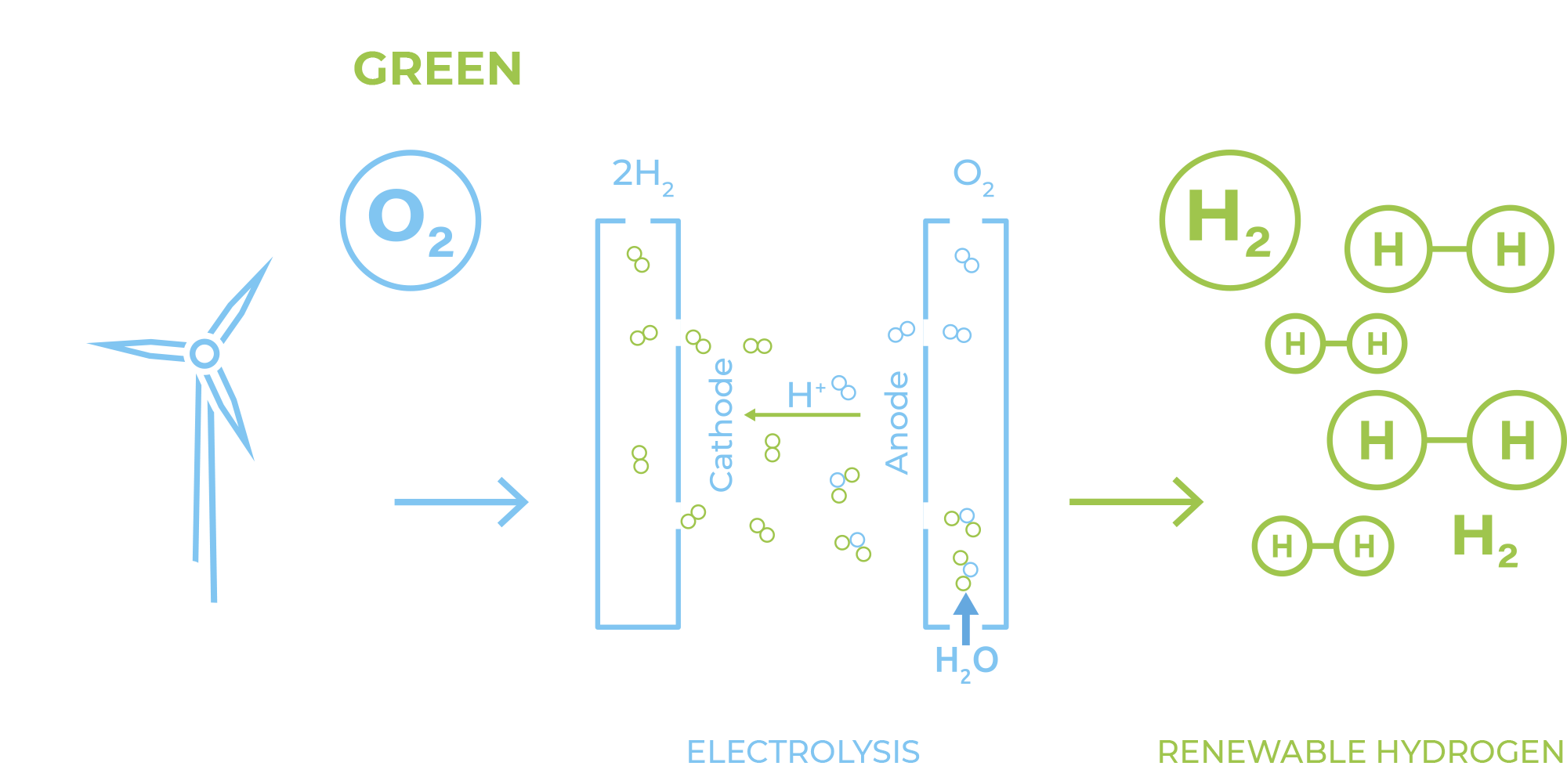

How hydrogen is produced

Around 95% of the world’s current hydrogen supply is obtained by steam-reforming fossil fuels. Green hydrogen, with very little embedded carbon-dioxide emission, is produced from green electricity by electrolysis.

The current global green hydrogen supply capacity is relatively tiny but growing at a rate limited by suppliers’ capacities to build new electrolysers. According to a recent report by the International Energy Agency [1], the installed electrolyser capacity will exceed 1 GW (measured as input electric power) by the end of 2022 and production is growing at 8 GW per year, with more than USD 1.5 billion spent in 2021 on projects with a final investment decision and under construction. By 2030, the current pipeline of projects is expected to lead to 134 – 200 GW of capacity if all planned projects proceed, with around 30% of that in Australia. To put this amount of power in perspective, the average peak electricity demand in the National Electricity Market is around 30 GW.

In an electrolyser, the supplied electric energy is used to split the water molecule (H2O) into its constituent hydrogen (H2) and oxygen (O2) at an energy cost of about 55 kWh of electricity per kilogram of hydrogen produced. The process ideally consumes 9 litres of water per kg H2 produced, although about twice this much is used in practice, with the balance forming a still relatively pure waste stream. The feedwater must be very pure to avoid poisoning the electrodes of the electrolyser; typically, “town” water is further purified by reverse osmosis. The hydrogen and oxygen are both highly pure; the hydrogen is suitable for use in fuel-cells to generate electricity and the oxygen is better than medical grade.

The infrastructure

PHASE 1: ONSHORE

In Phase I, now underway, a 700 kW ITM Power HGAS1SP PEM (Proton Exchange Membrane) electrolyser will be powered with green electricity to generate up to 262 kg of gaseous hydrogen per day.

PEM electrolysis is a newer, simpler technology than conventional alkaline electrolysis.

The hydrogen will be managed by a hydrogen microgrid, being built by CRC partner Optimal Group, that incorporates a photovoltaic array, battery, Capstone C65 turbine electricity generator and hydrogen storage. The hydrogen microgrid is hosted by BOC at its Lutana site in Hobart.

Hydrogen produced by the microgrid in Hobart will be accumulated by compression into a tube trailer holding about 400kg H2 at 16.5 MPa (163 atmospheres) pressure.

The tube trailer will then be collected and connected to a hydrogen refuelling station, while another tube trailer is connected to the microgrid for filling.

The electrolyser will produce about 1.8 tonne of hydrogen per week at full capacity, leaving hydrogen available for other offtakes and for research purposes.

PROJECT PARTNERS

How hydrogen will be used

The microgrid has dual purposes: to supply hydrogen to power Tasmania’s fuel-cell buses (“offtake” of compressed hydrogen by means of tube trailers) and to support research into the operation of DC hydrogen microgrids.

For this second purpose, the microgrid also incorporates a programmable electricity source that can emulate, for example, a wind turbine or wave energy converter, and a programmable load that can emulate the electrical load profile of applications such as an aquaculture site, vessel operations, island communities or remote areas like Antarctica.

How hydrogen will be used

The microgrid has dual purposes: to supply hydrogen to power Tasmania’s fuel-cell buses (“offtake” of compressed hydrogen by means of tube trailers) and to support research into the operation of DC hydrogen microgrids.

For this second purpose, the microgrid also incorporates a programmable electricity source that can emulate, for example, a wind turbine or wave energy converter, and a programmable load that can emulate the electrical load profile of applications such as an aquaculture site, vessel operations, island communities or remote areas like Antarctica.

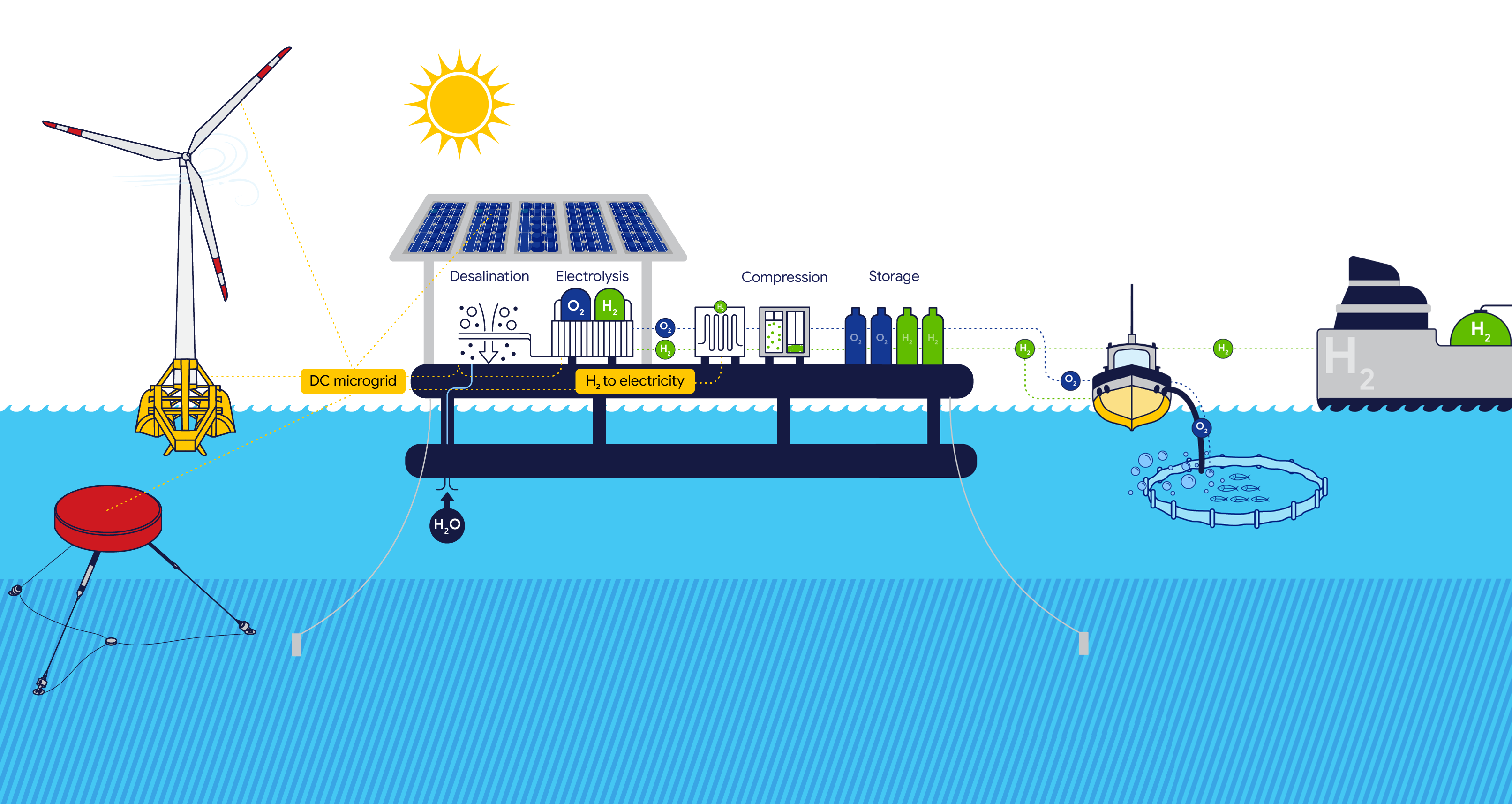

PHASE II: OFFSHORE

Phase II of the project will see a hydrogen microgrid built at an offshore location to be determined. The configuration shown is built around aquaculture, with oxygen (the co-product of electrolysis of water) supplied for use in aquaculture and hydrogen supplied for powering vessels.

2. Desalination

Seawater must be desalinated for use in currently available electrolysers. This happens by a combination of filtration, reverse osmosis and deionisation. The by-product of fuel-cell operation is high-purity water, which is captured to lessen the need for further desalination.

5. Storage

High-pressure hydrogen tanks hold enough hydrogen to guarantee supply of both hydrogen and electricity.

DECARBONISING OFFSHORE AQUACULTURE OPERATIONS

Consumers are increasingly focused on food and energy security, sustainability and provenance. Already, we are seeing strong international demand for offshore renewable energy and for sustainably farmed offshore aquaculture.

The Aquaculture Centre of Excellence aims to revolutionise fish farming with its eco-friendly, cost effective and sustainable technology Eco-Ark®.

With the Blue Economy CRC’s new collaboration with ACE®, we will work together on R&D that will fully decarbonise offshore aquaculture operations, using offshore renewable energy technologies used to produce electricity and hydrogen offshore, optimal solutions for offshore energy storage, hydrogen-powered vessels, and develop an innovative approach to feeding and nutrition, on the Eco-Ark® aquaculture facility.

Related Research Projects

In parallel with the pioneering demonstration project that will put physical infrastructure in place to supply and manage electricity and hydrogen onshore and offshore, research projects within RP3 and other research programs are addressing research questions to underpin the design and operation of the Phase-I and Phase-II hydrogen microgrids:

Progress Milestones

Agreements have been reached with the Tasmanian Government to supply hydrogen fuel to Tasmania’s fuel-cell bus project, and with BOC to host the hydrogen microgrid at its Lutana industrial site in Hobart.

Procurement of the other components of the Phase-1 hydrogen microgrid is well advanced the Capstone C65 turbine generator has been received and commissioned on pure hydrogen fuel, producing very low NOx emissions; the 90 kW programmable load has been received; two hydrogen compressors for tandem operation, a battery with approximately 115 kWh capacity and an 18 kW programmable generator have been ordered.

The power supply for the electrolyser has been received in Australia and the electrolyser stack is undergoing final acceptance testing for shipping in May 2023.

Preliminary design work for the hydrogen microgrid has been completed and detailed engineering design is underway.

Contracts for civil, mechanical and electrical works at Lutana Hobart have been let.

Commissioning onshore hydrogen microgrid in July 2023 . Onshore operations will continue for a 3 year period.

Phase II Offshore hydrogen production to commence in 2026.

The BE CRC hydrogen microgid project will be one of the pilot projects under the Guarantee of Origin (GO) Trial – a world-class assurance scheme being designed to track and verify emissions associated with hydrogen, renewable electricity and potentially other products made in Australia. The scheme design is the result of extensive consultation by the Department of Climate Change, Energy, the Environment and Water (the Department) and the Clean Energy Regulator (CER). Pitt&Sherry, Hydro Tasmania and BOC have participated in multiple workshops run by the Clean Energy Regulator in establishing the GO trial. Find out more