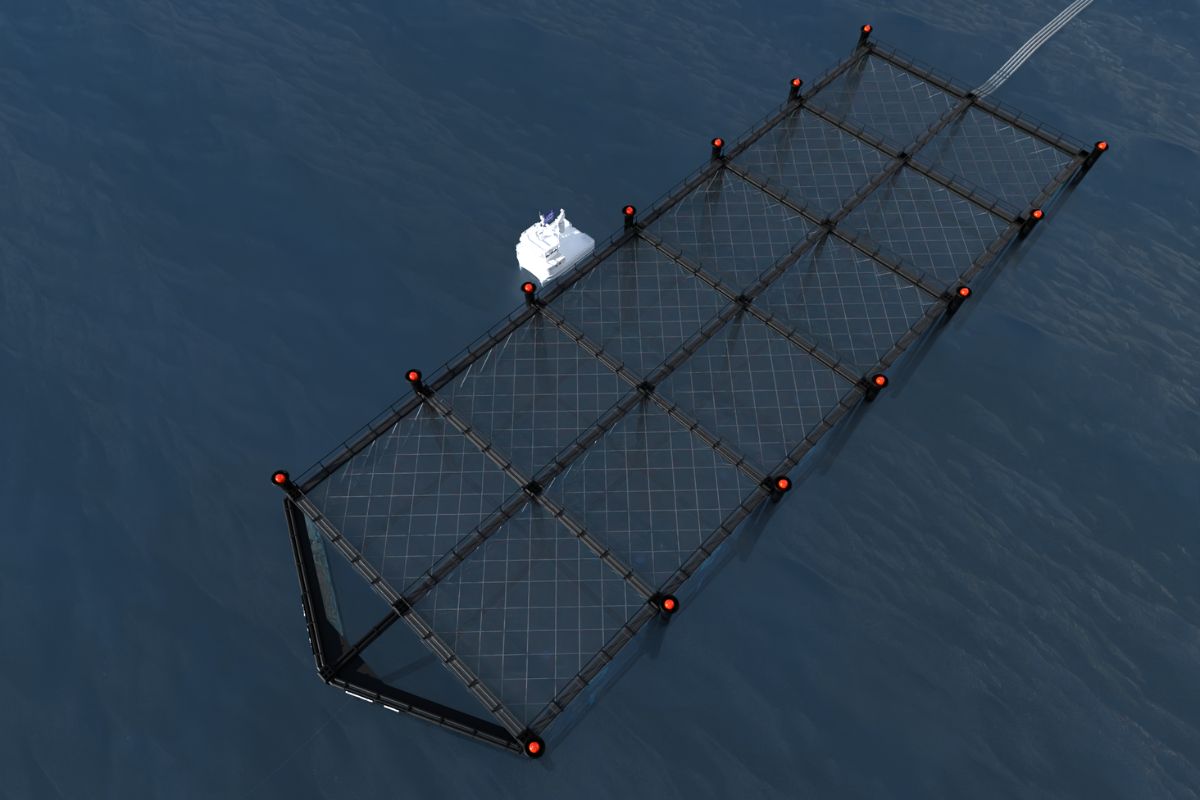

Image courtesy of AEX Group

Research Program

PROJECT LEADER

PROJECT ID

1.21.002

BECRC PARTNERS

Auckland University of Technology

Cawthron

DNV Australia

Griffith University

Huon Aquaculture

SINTEF

Tassal Group

TCOMS

Universidad Austral de Chile

University of Queensland

UTAS

START DATE

February 2022

END DATE

January 2024

DURATION

24 months

PROJECT IN BRIEF

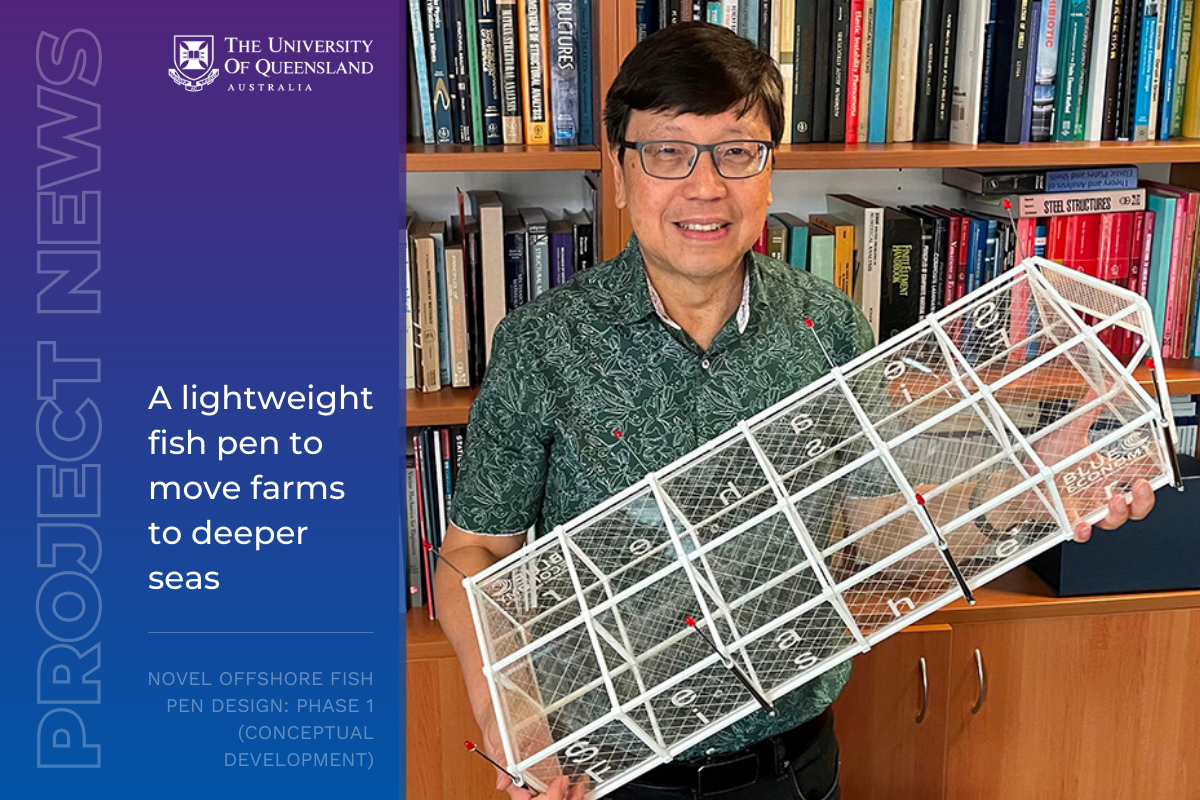

With fish farming moving from onshore to offshore, a novel fish pen design is needed. The scoping study “Review of Fish Pen Designs and Mooring Systems” by C. M. Wang et al. (2020) provided an overview of current challenges and future design opportunities for offshore fish pens.

Based on that, two new design schemes called SeaFisher and SeaDipper evolved. Submitted as a patent application, they reduce the wave load by either elevating or submerging the main parts of the structure.

Linked with the other BECRC programs, this project proposal will develop the SeaDipper and SeaFisher conceptually further to create safer, more efficient and affordable offshore fish pen structures.

Two major industry partners (Tassal Group and Huon Aquaculture) with broad operational expertise will participate and co-select the most promising concepts of the SeaFisher and SeaDipper during this first phase before the concepts will be improved and tested in detail, prototyped, and commercialised in the subsequent two phases.

RELATED NEWS

December 2023 Progress Update

The project team is pleased to announce it has successfully developed an innovative, practical, and cost-effective conceptual design for the SeaFisher. This design is well-suited for deployment in exposed sites globally.

The SeaFisher uses high-density polyethylene (HDPE) pipes and connectors to construct modular frame structures, ensuring easy fabrication, high flexibility, and cost-effectiveness. Its longitudinal-shaped structure, combined with a single-point mooring, effectively minimises environmental loads. Furthermore, the SeaFisher is designed to be submersible, providing protection against strong surface waves during storms through a sophisticated ballasting system.

October 2023 Progress Update

A patent was filed in August for an innovative modular Aquaculture Construction Kit made from High-Density Polyethylene (HDPE), a popular choice for coastal aquaculture structures such as fish pens. The modular nature of this system not only provides flexibility in design but also offers cost-effective production and transportation, as well as rapid assembly and disassembly, both on land and in water in combination with HDPE’s advantages like affordability, recyclability, as well as resistance to UV radiation and to biofouling.

These coastal and offshore structures have the ability to float or submerge, depending on the requirements. As a result, they may find application in various scenarios, including fish pens, shellfish cultivation, algae and kelp farming, and even as floating platforms to support aquaculture operations.